Home / News / Industry News / CNC Precision Machining for Electronics: Achieving Micron-Level Accuracy

CNC Precision Machining for Electronics: Achieving Micron-Level Accuracy

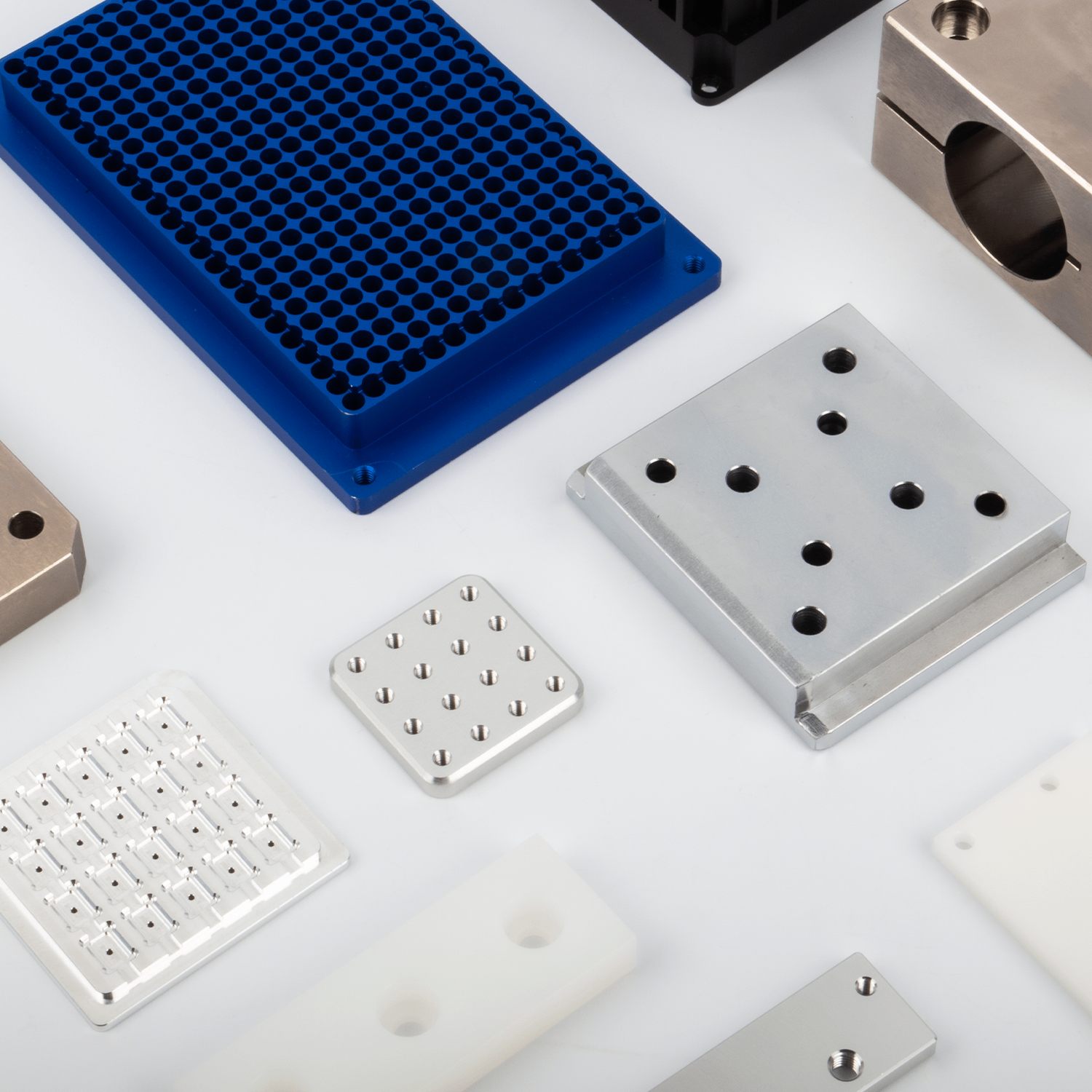

In today’s rapidly evolving electronics industry, the demand for high-precision components has never been greater. From microprocessors and semiconductor devices to advanced sensors and connectors, modern electronics rely heavily on components manufactured with micron-level accuracy. Achieving such precision is no longer optional—it is a fundamental requirement to ensure functionality, reliability, and longevity. One of the most effective solutions to meet these demanding specifications is CNC precision machining.

Understanding CNC Precision Machining in Electronics

CNC, or Computer Numerical Control, precision machining refers to the use of computer-controlled tools to manufacture components with extremely tight tolerances and complex geometries. Unlike traditional manual machining, CNC machines execute pre-programmed instructions with exceptional consistency, ensuring that every part meets exact specifications.

In the electronics sector, CNC precision machining is often used for producing components such as:

Micro connectors and pins

Semiconductor wafers and housings

Heat sinks and thermal management components

Precision enclosures for sensors and MEMS devices

Custom PCB milling and drilling

The common denominator for all these applications is the requirement for micron-level accuracy, typically in the range of 1 to 10 microns, depending on the application. Achieving this level of precision requires not only advanced machinery but also meticulous planning and process control.

Why Micron-Level Accuracy Matters in Electronics

Modern electronics components are increasingly miniaturized, with tighter tolerances and more intricate designs. In such an environment, even a deviation of a few microns can cause significant issues, such as:

Electrical Malfunctions: Misaligned connectors or PCB traces can disrupt the electrical flow, leading to component failure.

Thermal Inefficiency: Improperly machined heat sinks or enclosures may impair heat dissipation, affecting performance and longevity.

Assembly Challenges: Parts that do not meet tight tolerances may not fit correctly during automated assembly, increasing production costs.

Signal Integrity Issues: In high-frequency electronics, even small geometric deviations can lead to signal reflection, noise, or interference.

Therefore, precision is not just a technical advantage—it directly impacts product quality, reliability, and competitiveness in the electronics market.

Key CNC Machining Techniques for Electronics

To achieve micron-level accuracy, several specialized CNC machining techniques are commonly employed in the electronics industry:

1. High-Speed Milling

High-speed milling uses advanced spindles and tooling to remove material at extremely high rotation speeds. This reduces cutting forces and heat generation, which is critical when working with delicate electronic components. High-speed milling is particularly effective for creating intricate features on small components, such as connectors and housings.

2. Micro-Drilling and Micro-Threading

Micro-drilling allows for the creation of holes as small as 0.1 mm, essential for printed circuit boards (PCBs) and sensor housings. Micro-threading is also possible, enabling secure fastenings in miniature assemblies. These processes require specialized CNC machines with vibration-damping systems to maintain accuracy.

3. Ultra-Precision Turning

Ultra-precision CNC lathes can produce cylindrical components with tolerances in the sub-micron range. This technique is widely used for manufacturing shafts, pins, and contacts in electronic assemblies. By combining high spindle speeds with precision feedback systems, manufacturers can achieve smooth surface finishes and tight dimensional control.

4. Electrical Discharge Machining (EDM)

EDM uses electrical sparks to erode conductive materials, allowing the creation of highly precise features that would be difficult or impossible with traditional cutting tools. This method is ideal for complex geometries, sharp corners, and fine slots commonly required in electronics components.

5. Multi-Axis CNC Machining

Multi-axis CNC machines, such as 5-axis or 6-axis systems, enable machining from multiple directions without repositioning the part. This capability is critical for complex electronics components, reducing setup errors and ensuring consistent micron-level tolerances throughout the entire part.

Material Considerations in CNC Machining for Electronics

The choice of material significantly affects the machining process and achievable precision. Common materials used in electronics include:

Aluminum and Copper Alloys: Widely used for housings and heat sinks due to their excellent thermal conductivity.

Stainless Steel: Ideal for structural components requiring strength and corrosion resistance.

Plastics and Polymers: Such as PEEK or Ultem, used for insulating components and connectors.

Ceramics: For high-temperature or high-frequency applications where metals may not suffice.

Each material requires careful selection of tooling, feed rates, and cutting parameters to maintain micron-level accuracy and prevent defects like burrs or thermal distortion.

Quality Control and Inspection

Maintaining micron-level accuracy demands rigorous quality control throughout the CNC machining process. Key inspection techniques include:

Coordinate Measuring Machines (CMM): Provides highly accurate 3D measurements of machined components.

Laser Scanning and Optical Profilometry: Non-contact methods for measuring surface profiles and detecting micro-defects.

Microscopic Inspection: For checking fine features, holes, and threads.

Statistical Process Control (SPC): Monitoring production data to ensure consistent machining quality over large batches.

Integrating these inspection techniques with CNC machining ensures that every component meets stringent electronic industry standards.

Challenges in CNC Machining for Electronics

Despite its advantages, CNC precision machining in electronics presents several challenges:

Thermal Expansion: High-speed machining generates heat, which can cause materials to expand and affect tolerances.

Tool Wear: Precision tooling wears quickly when machining hard metals or abrasive materials, requiring frequent replacement.

Vibration Control: Even minor vibrations can disrupt micron-level accuracy, necessitating specialized damping systems.

Programming Complexity: Micron-level machining often requires highly sophisticated CAM programming to optimize tool paths and reduce errors.

Addressing these challenges requires a combination of advanced machinery, skilled operators, and robust process planning.

Advantages of CNC Precision Machining for Electronics

When executed correctly, CNC precision machining offers numerous benefits for electronics manufacturers:

Unmatched Accuracy: Consistent micron-level tolerances across all components.

Repeatability: Ability to reproduce parts with identical specifications, essential for mass production.

Flexibility: Easy adaptation to new designs without major retooling.

Complex Geometries: Capability to machine intricate features that would be impossible with traditional methods.

Reduced Waste: High precision minimizes material scrap, improving cost efficiency.

These advantages make CNC precision machining a cornerstone of modern electronics manufacturing.

Future Trends

As electronics continue to evolve, CNC precision machining will advance alongside:

Automation and Robotics: Fully automated CNC lines will increase throughput while maintaining micron-level precision.

Integration with Additive Manufacturing: Hybrid approaches combining 3D printing and CNC machining for complex electronics components.

Smart CNC Machines: AI-driven optimization and predictive maintenance to enhance precision and reduce downtime.

Miniaturization: Demand for even smaller and more precise components will push the limits of machining accuracy further.

The combination of these trends ensures that CNC precision machining remains indispensable for the electronics industry.

Conclusion

CNC precision machining has transformed the electronics industry by enabling the production of highly complex components with micron-level accuracy. From high-speed milling and ultra-precision turning to micro-drilling and multi-axis machining, the technology allows manufacturers to meet the exacting standards of modern electronic devices. While challenges such as thermal expansion, tool wear, and vibration exist, the benefits—including unparalleled accuracy, repeatability, and flexibility—far outweigh them.

As electronics continue to become smaller, faster, and more sophisticated, CNC precision machining will remain at the forefront, ensuring that each component performs flawlessly in even the most demanding applications.

Shenzhen Xinbanghui Hardware Products Co., Ltd. provides professional CNC precision machining services, offering high-accuracy solutions tailored for the electronics industry, helping manufacturers achieve the exacting standards required for modern electronic devices

Hot Product

Hot Product

-

Bearing flange for medical equipmentRead moreBearing flange for medical equipment

Bearing flange for medical equipmentRead moreBearing flange for medical equipment -

Turning and milling composite precision brass rod sleeveRead moreTurning and milling composite precision brass rod sleeve

Turning and milling composite precision brass rod sleeveRead moreTurning and milling composite precision brass rod sleeve -

Precision milling of joint product toolingRead morePrecision milling of joint product tooling

Precision milling of joint product toolingRead morePrecision milling of joint product tooling -

Automation equipment precision stainless steel suction nozzleRead moreAutomation equipment precision stainless steel suction nozzle

Automation equipment precision stainless steel suction nozzleRead moreAutomation equipment precision stainless steel suction nozzle -

CNC titanium alloy precision square parts processingRead moreCNC titanium alloy precision square parts processing

CNC titanium alloy precision square parts processingRead moreCNC titanium alloy precision square parts processing -

Medical device connector bracketRead moreMedical device connector bracket

Medical device connector bracketRead moreMedical device connector bracket