Aerospace CNC Machining for Complex Titanium and Aluminum Parts

In the aerospace industry, the demand for high-performance components is continually growing. Aircraft and spacecraft rely on parts that are not only lightweight but also capable of withstanding extreme stress, temperature fluctuations, and corrosive environments. This is where aerospace CNC machining for complex titanium and aluminum parts becomes critical. With the evolution of computer numerical control (CNC) technology, manufacturers can achieve unparalleled precision, efficiency, and repeatability in producing intricate aerospace components.

Understanding Aerospace CNC Machining

CNC machining refers to a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. In aerospace applications, CNC machining enables the production of parts with complex geometries that are difficult—or even impossible—to achieve through traditional machining methods. Components such as turbine blades, structural airframe elements, and engine mounts often require tight tolerances and smooth surface finishes, both of which are achievable through advanced CNC machining.

For aerospace applications, the focus is often on two critical materials: titanium and aluminum. Each material presents unique challenges and opportunities, making CNC machining a tailored and highly technical process.

Why Titanium and Aluminum are Preferred in Aerospace

Titanium

Titanium alloys, especially Ti-6Al-4V, are renowned for their high strength-to-weight ratio, excellent corrosion resistance, and ability to withstand extreme temperatures. These properties make titanium ideal for components such as:

Engine components and fan blades

Landing gear parts

Structural airframe elements

However, titanium is notoriously difficult to machine due to its low thermal conductivity and high chemical reactivity. Without proper machining techniques, titanium parts can suffer from tool wear, poor surface finish, and dimensional inaccuracies.

Aluminum

Aluminum alloys, particularly 7075 and 6061, are widely used in aerospace for their lightweight properties, high strength, and corrosion resistance. Aluminum is easier to machine compared to titanium, but achieving tight tolerances and surface finishes for critical aerospace applications still demands advanced CNC equipment and expert operators.

Aluminum parts commonly include:

Airframe panels

Aircraft structural components

Hydraulic and fuel system parts

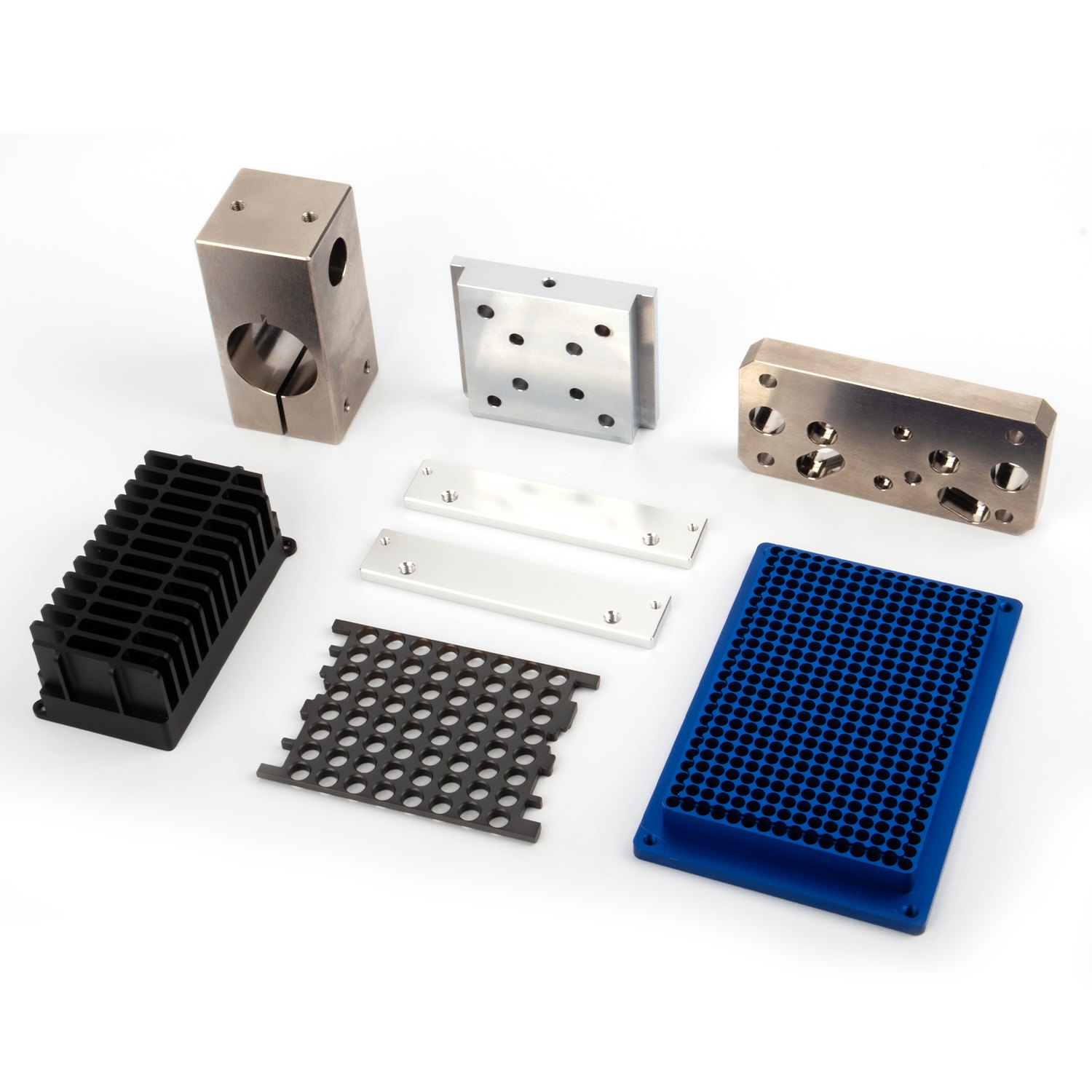

Key CNC Machining Techniques for Complex Aerospace Parts

Aerospace CNC machining requires a combination of precision, speed, and adaptability. Some of the key machining techniques include:

1. Multi-Axis Milling

Multi-axis CNC machines (3-axis, 4-axis, and 5-axis) enable manufacturers to machine intricate geometries in a single setup. This reduces errors and improves efficiency. For titanium and aluminum components with curved surfaces, pockets, or angled features, multi-axis milling ensures high accuracy and minimal manual intervention.

2. Turning and Lathe Operations

For cylindrical or rotational components, CNC lathes offer precision turning. This is crucial for aerospace components such as landing gear struts, shafts, and fasteners, where dimensional tolerances are critical.

3. Drilling and Tapping

Titanium and aluminum aerospace parts often require multiple threaded holes, countersinks, and precise drilling patterns. CNC drilling and tapping allow for consistent hole placement and depth control, which is vital for assembly and structural integrity.

4. High-Speed Machining (HSM)

HSM techniques improve surface finish, reduce cycle times, and minimize heat generation, particularly important for titanium. These methods rely on advanced toolpath strategies and optimized spindle speeds to maintain part integrity.

5. Tooling and Coolant Management

Tool selection is crucial in aerospace CNC machining. Carbide, coated carbide, and diamond tools are often used for high-strength alloys. Proper coolant management prevents thermal distortion and prolongs tool life, ensuring dimensional accuracy.

Quality Control in Aerospace CNC Machining

Given the critical nature of aerospace components, quality control (QC) is non-negotiable. Modern aerospace CNC facilities implement:

In-process inspection using coordinate measuring machines (CMMs)

Surface finish analysis for aerodynamic or structural surfaces

Non-destructive testing (NDT), including X-ray and ultrasonic testing

Tight tolerance verification, often within microns

These measures ensure that each part meets strict aerospace standards, such as AS9100 certification requirements.

Applications of Complex Titanium and Aluminum Parts

The aerospace industry demands a wide range of parts with complex geometries and high-performance characteristics. Some typical applications include:

Engine Components: Turbine blades, compressors, and casings often require titanium for high-temperature resistance.

Structural Parts: Aluminum frames, bulkheads, and brackets provide lightweight yet strong support.

Landing Gear: High-strength titanium components endure extreme loads during takeoff and landing.

Interior Aerospace Systems: Brackets, panels, and fasteners require precise machining for assembly and safety compliance.

Advantages of CNC Machining in Aerospace

CNC machining for complex titanium and aluminum parts offers several distinct advantages:

Precision and Accuracy: CNC machines can achieve tolerances as tight as ±0.001 inches, critical for aerospace assemblies.

Repeatability: Multiple identical parts can be produced with consistent quality.

Reduced Lead Times: Advanced programming and multi-axis machining reduce production cycles.

Cost Efficiency: Although initial investment is high, CNC machining reduces material waste and rework.

Flexibility: CNC machining easily accommodates design changes and new part geometries without extensive retooling.

Future Trends in Aerospace CNC Machining

The aerospace sector is continuously evolving, and CNC machining is advancing along with it. Key trends include:

Automation and Robotics: Integration of robotic loading/unloading and in-line inspection reduces human error and improves throughput.

Hybrid Manufacturing: Combining CNC machining with additive manufacturing (3D printing) enables complex geometries that were previously impossible.

Smart CNC Systems: AI-driven optimization of toolpaths, predictive maintenance, and real-time monitoring enhance efficiency and part quality.

Sustainable Machining: Techniques that minimize energy consumption, coolant usage, and material waste are increasingly important for green aerospace manufacturing.

Conclusion

Aerospace CNC machining for complex titanium and aluminum parts is a cornerstone of modern aircraft and spacecraft production. By combining advanced multi-axis CNC machines, expert tooling, and rigorous quality control, manufacturers can produce components that meet the stringent demands of the aerospace industry. As technology evolves, the integration of automation, hybrid manufacturing, and smart CNC systems promises to further enhance precision, efficiency, and sustainability in aerospace production.

For companies seeking reliable, high-performance titanium and aluminum aerospace parts, partnering with a specialized aerospace CNC machining manufacturer is essential. From engine components to structural assemblies, precision CNC machining ensures the safety, reliability, and innovation that the aerospace industry requires.

Hot Product

Hot Product

-

Bearing flange for medical equipmentRead moreBearing flange for medical equipment

Bearing flange for medical equipmentRead moreBearing flange for medical equipment -

Turning and milling composite precision brass rod sleeveRead moreTurning and milling composite precision brass rod sleeve

Turning and milling composite precision brass rod sleeveRead moreTurning and milling composite precision brass rod sleeve -

Precision milling of joint product toolingRead morePrecision milling of joint product tooling

Precision milling of joint product toolingRead morePrecision milling of joint product tooling -

Automation equipment precision stainless steel suction nozzleRead moreAutomation equipment precision stainless steel suction nozzle

Automation equipment precision stainless steel suction nozzleRead moreAutomation equipment precision stainless steel suction nozzle -

CNC titanium alloy precision square parts processingRead moreCNC titanium alloy precision square parts processing

CNC titanium alloy precision square parts processingRead moreCNC titanium alloy precision square parts processing -

Medical device connector bracketRead moreMedical device connector bracket

Medical device connector bracketRead moreMedical device connector bracket