Home / News / Industry News / CNC milling aluminum parts processing service: professional customized aluminum parts

CNC milling aluminum parts processing service: professional customized aluminum parts

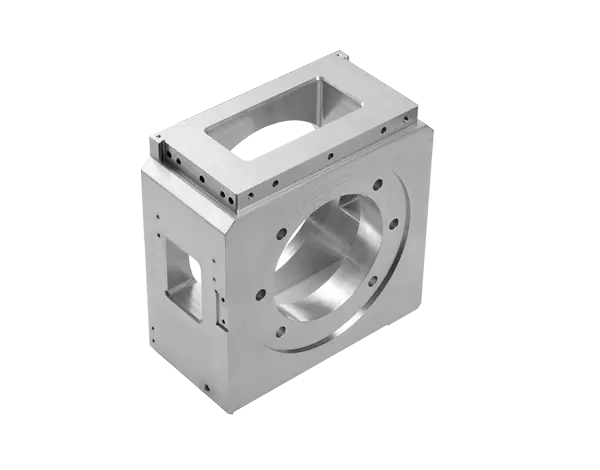

In modern manufacturing, aluminum alloy has become a widely used metal material due to its light weight, high strength, corrosion resistance and excellent processing performance. Whether in the field of automobile manufacturing, aerospace, or electronic equipment and mechanical parts, the demand for aluminum parts continues to grow. In order to meet the diverse and personalized needs of customers, CNC milling aluminum parts processing services have emerged. With its high precision, high efficiency and strong customization capabilities, it has become an important choice in the field of aluminum parts processing.

This article will comprehensively introduce the advantages, process flow, technical points of CNC milling aluminum parts processing services and how to provide a full range of solutions for your customized projects to help improve your product quality and market competitiveness.

1. What is CNC milling aluminum parts processing?

CNC milling refers to the process of precision cutting aluminum alloy workpieces through CNC milling machines with the help of computer programs. The CNC system accurately controls the tool path, cutting speed, feed rate and other parameters according to the pre-designed processing program to achieve aluminum parts processing with complex shapes and high-precision dimensions. Compared with traditional manual or ordinary mechanical processing, CNC milling greatly improves the automation and stability of processing.

As an important processing object of CNC milling, aluminum parts play a core role in many industries due to their light weight, fast heat conduction, and easy forming. Through CNC milling, the personalized customization needs of different customers can be met to create high-quality and high-performance aluminum parts.

2. Advantages of CNC milling aluminum parts processing

High-precision and complex shape processing capabilities: CNC milling equipment has high precision, and common processing tolerances can reach ±0.01mm or even higher. Complex curved surfaces, tiny structures, multiple holes and other aluminum parts can be processed efficiently to meet customers' needs for complexity.

Automation and high efficiency: Automated CNC programs reduce manual operation errors and improve production efficiency. In batch production, maintain product size consistency and achieve fast delivery.

Good surface quality: CNC milling is combined with appropriate tools and cutting parameters, and the surface of aluminum parts is smooth and flat, reducing subsequent grinding and polishing processes and improving overall processing efficiency.

Flexible customization capabilities: CNC processing programs can be adjusted quickly, suitable for small batch and multi-variety production, meeting customers' personalized customization and rapid sample development needs.

Reduce material waste: Precision cutting reduces the waste of excess materials, saves costs, and conforms to the modern green manufacturing concept.

3. Application fields and customized service advantages

Our CNC milling aluminum parts processing services cover a variety of customized needs from single samples to mass production, and are widely used in the following industries:

Aerospace: The aerospace field has extremely high requirements for the precision and performance of aluminum parts. Through high-precision CNC milling technology, the processed aluminum alloy parts are not only lightweight and high-strength, but can meet the durability and safety requirements of complex structures.

Automobile manufacturing: Automobile engine parts, chassis structural parts and decorative parts all require efficient and precise aluminum parts processing. CNC milling ensures that the parts are accurate in size and smooth on the surface, while achieving batch processing and improving production efficiency.

Electronic products: High-performance aluminum alloy radiators, housings and structural parts require delicate processing details and meet the standards of tight assembly. CNC milling can achieve complex microstructures with stable processing effects.

Medical devices: Medical equipment parts are usually small in size and complex in structure, and the requirements for materials and precision are very strict. CNC milling can meet these high standards, process high-quality aluminum parts, and ensure equipment performance and safety.

Industrial machinery and automation: Aluminum parts in automation equipment are diverse and complex. CNC milling provides high-precision parts customization for industrial machinery, supporting the stable operation and efficient production of mechanical equipment.

4. CNC milling aluminum parts processing process

Customer demand communication and solution design: The customer provides product design drawings or 3D models, and the technical team formulates a reasonable processing plan based on design requirements and aluminum characteristics, including tool selection, processing path, cutting parameters, etc.

Compilation of CNC programs: Professional programmers use CAD/CAM software (such as Mastercam, UG, etc.) to generate CNC codes, simulate the processing process, optimize the processing path, and avoid interference and collision.

Raw material preparation: Select aluminum alloy materials of appropriate grades (such as 6061, 7075, etc.) according to customer requirements to ensure that the material quality meets the standards.

CNC milling processing: Import the program into the CNC milling machine for rough processing, semi-finishing and finishing. Monitor the operating status of the equipment during the process to ensure processing quality.

Quality inspection: After processing, use instruments such as coordinate measuring machines (CMMs) and vernier calipers to inspect dimensions and tolerances to ensure that they meet customer requirements.

Post-processing and surface treatment: Deburring, polishing, anodizing, electroplating and other surface treatment processes are carried out according to requirements to improve the appearance and durability of aluminum parts.

Packaging and delivery: Products that have undergone strict quality inspection are packaged according to customer requirements and delivered in a timely manner.

5. Advantages of our customized CNC milling aluminum parts processing service

Professional team support: With experienced engineers and programming experts, we provide precise process solutions for your aluminum parts customization.

Advanced equipment guarantee: Introduce advanced CNC milling machines from home and abroad, equipped with high-performance tools and testing equipment to ensure efficient and stable processing.

Strict quality control: Full-process quality monitoring to ensure that the dimensional accuracy and surface quality of each aluminum part meet international standards.

Quick response and delivery: Flexible scheduling of production to meet the needs of small batches and rapid delivery, helping customers seize market opportunities.

Personalized service: Tailor-made processing solutions according to customers' specific needs and drawings, flexibly adjust processing parameters, and achieve efficient and accurate customized production.

Timely delivery and high-quality after-sales service: An efficient production management system guarantees the delivery cycle, and a professional customer service team provides technical support and after-sales service to ensure that customers are worry-free.

CNC milling aluminum processing is not only a reflection of technology, but also a commitment to quality and efficiency. We are committed to providing customers with full-process support from design consultation, processing and manufacturing to post-sales service. Whether it is a single sample or batch production, we can meet your high standards for aluminum quality.

If you are looking for a professional, reliable and efficient CNC milling aluminum processing partner, please contact us. We will provide tailor-made processing solutions for your customized projects to help your products stand out in the market. Contact us to start your journey of high-quality CNC milling aluminum customization!

Hot Product

Hot Product

-

Bearing flange for medical equipmentRead moreBearing flange for medical equipment

Bearing flange for medical equipmentRead moreBearing flange for medical equipment -

Turning and milling composite precision brass rod sleeveRead moreTurning and milling composite precision brass rod sleeve

Turning and milling composite precision brass rod sleeveRead moreTurning and milling composite precision brass rod sleeve -

Precision milling of joint product toolingRead morePrecision milling of joint product tooling

Precision milling of joint product toolingRead morePrecision milling of joint product tooling -

Automation equipment precision stainless steel suction nozzleRead moreAutomation equipment precision stainless steel suction nozzle

Automation equipment precision stainless steel suction nozzleRead moreAutomation equipment precision stainless steel suction nozzle -

CNC titanium alloy precision square parts processingRead moreCNC titanium alloy precision square parts processing

CNC titanium alloy precision square parts processingRead moreCNC titanium alloy precision square parts processing -

Medical device connector bracketRead moreMedical device connector bracket

Medical device connector bracketRead moreMedical device connector bracket